Mon May 16 11:59:28 CST 2022

Today, Longteng Hardware brings you the introduction of four common rivet nuts, rivet nuts, rivet nuts, rivet nuts, and rivet nuts, and their comparison of drilling and tapping.

Now I will introduce these four kinds of nuts to you.

One.Brivet nuts

Pull riveting refers to that in the process of riveting, the riveted parts are deformed under the action of external tension, and the position of the deformation is consistent.

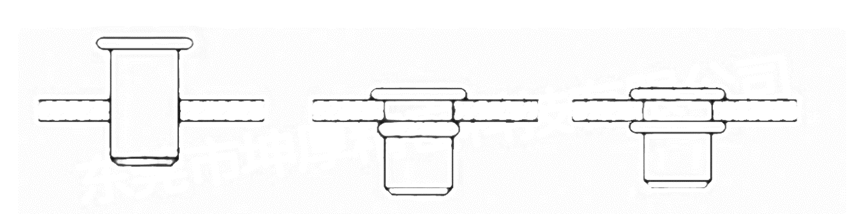

Often in specially designed parts, a reliable connection is achieved by clamping the substrate at the deformed part. The commonly used rivet nuts are connected to the base material by using different types of riveting. Pull riveting uses a special riveting gun for riveting, which is mostly used when the installation space is small and general riveting tooling cannot be used, such as closed pipes. The riveting of the rivet nut is shown in the figure:

Schematic diagram of the riveting process

Insert fasteners Deformation under force riveting completed

Two. Pressure riveting nut column

Press riveting means that in the process of riveting, under the external pressure, the pressure riveting part causes the plastic deformation of the base material, and squeezes it into the special prefabricated groove in the riveting screw and nut structure, so as to realize the palm connection of the two parts. There are two kinds of non-standard nuts for pressure riveting:

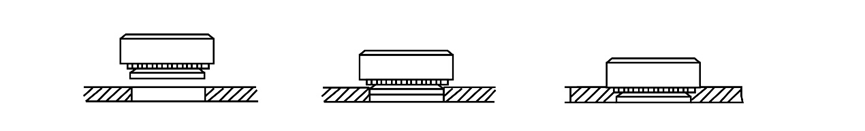

One is the pressure riveting standoff, and the other is the pressure riveting nut. This riveting form is used to realize the connection with the base material. This riveting form usually requires that the hardness of the riveted parts is greater than that of the base material. Ordinary low carbon steel, aluminum alloy plate, and copper plate are suitable for crimping rivet standoffs. For stainless steel and high carbon steel plates, because of their hard materials, special high-strength standoffs are required, which are not only expensive, but also pressurized. The connection is difficult, the crimping is not reliable, and it is easy to fall off after crimping. In order to ensure the palmability, the manufacturer often needs to weld the side of the nut column, and the workmanship is not good. Gold parts are not made of stainless steel as much as possible. This is also the case for pressure riveting screws and pressure riveting nuts, which are not suitable for use on stainless steel plates. The pressure riveting process of the pressure riveting standoff is shown in the figure:

Before riveting Deformation under force crimp completed

Three.Pressure riveting nut

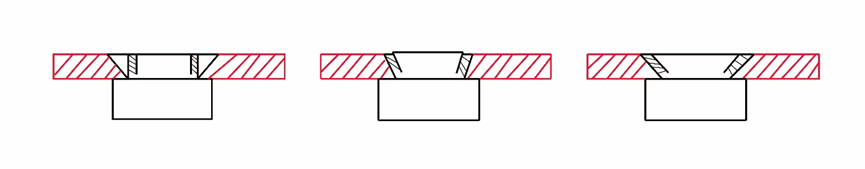

The rivet nut column above has been introduced, so let's go directly to the picture. The pressure riveting process of the pressure riveting nut is shown in the figure:

Before riveting Deformation under force crimp completed

Four.Riveting nut

Riveting refers to the way in which part of the material of the riveted screw or nut undergoes plastic deformation under the action of external force during the riveting process, and forms a close fit with the base material, thereby achieving a reliable connection between the two parts. Commonly used ZRS, etc. is to use this type of riveting to realize the connection with the base material. The riveting process is relatively simple and the connection strength is low. It is usually used when the height of the fastener is limited and the torque is not large.

Schematic diagram of the riveting process

Insert fasteners Deformation under force riveting completed

Finally, Dongguan Longteng Hardware Technology Co., Ltd. is a senior pressure riveting stud manufacturer, focusing on the production of stainless steel rivet nuts, rivet nuts, countersunk head rivet nuts, flat head rivet nuts, stainless steel waterproof nuts, waterproof standoffs, sealing nuts The source manufacturer of columns, waterproof rivet nuts, non-standard customization and other products for many years, with sufficient resources, complete specifications, high quality and fast delivery.